OUR

PROCESESS

Foundry

Our foundry features induction furnaces with production capacities of 80, 500, and 800 kilos per hour. This process focuses on the production of certified copper and aluminum alloys, transforming the material into a liquid state for the manufacture of ingots, bars, bushings, and injection-molded and sand-cast parts.

Semi-Continuous Casting

This process transforms the certified copper-aluminum alloy into a liquid. It then passes through a heat exchanger and solidifies to form various alloys: copper, brass, and bronze. The final products range in diameter from 25 mm to 120 mm and can be up to 4 meters in length.

Centrifuged

We manufacture concentric parts using copper and aluminum alloys using machines that rotate at high speeds, both vertically and horizontally. These parts have outer diameters ranging from 4" to 24", with lengths between 60 cm and 150 cm. The manufactured bushings are capable of withstanding the friction loads of any size shaft.

Sand Casting

In this process, the certified copper-aluminum alloy, in a liquid state, is poured into sand mold cavities of the required design. After cooling, the product is demolded, cleaned, and given the desired finish, such as shot peening, polishing, and/or machining. The resulting material is highly resistant to corrosion and has excellent machinability.

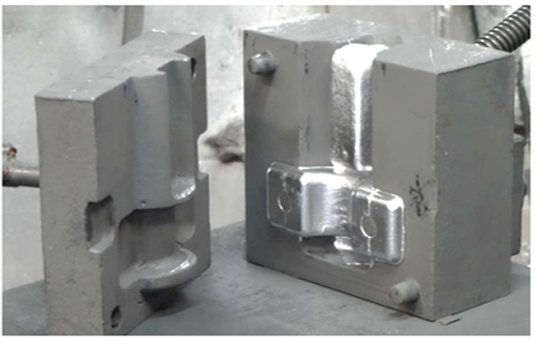

Injection

Using the injection molding process, the certified copper-aluminum alloy, in its liquid state, is introduced into a mold, where it is shaped to the required size. This process is designed to produce parts with a maximum weight of 1,000 grams, adapting to a variety of industrial applications.

Shelling

We manufacture concentric parts using copper and aluminum alloys using machines that rotate at high speeds, both vertically and horizontally. These parts have outer diameters ranging from 4" to 24", with lengths between 60 cm and 150 cm. The manufactured bushings are capable of withstanding the friction loads of any size shaft.

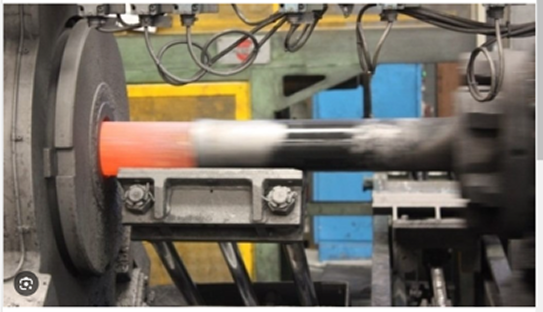

Extrusion

The extrusion process uses heated metal ingots to pass through a die that determines the cross-sectional shape of the product. The result is a continuous bar that is cut to the desired length and hardness. We offer a wide range of copper and brass bars and profiles, ranging in diameter from 3/16" to 4", in various geometric shapes.

In this hot forming process, brass parts are manufactured by dropping a die onto a billet of material in a plastic state, obtained by heat. We use presses with capacities ranging from 100 to 480 tons per stroke, punching machines, and shot blasting machines. The manufactured parts have excellent plasticity and high malleability.

Machining

To ensure maximum precision in the machining of parts, we employ five Mazak and Leadwell numerically controlled lathes, turret lathes, and arbor drills, among others. This high-tech equipment allows us to meet the most demanding standards of quality and precision.

Assembly

The assembly process is carried out by highly skilled labor, who are responsible for verifying and assembling the internal components of the meters. All meters and water service accessories undergo rigorous hydrostatic and leak testing, complying with current quality regulations.

Verification

Each meter undergoes a verification process, undergoing operational tests with high flow rates and an electronic regulation device. It is then volumetrically compared against properly calibrated standards to verify compliance with NTC ISO 4064-1 and -2.

Calibration Laboratory

BTP Medidores y Accesorios S.A. has a calibration laboratory accredited by ONAC (National Accreditation Body of Colombia) under the ISO IEC 17025 standard. This laboratory provides calibration services for water meters, from ½" to 1" sizes, with flow rates between 5 l/h and 600 l/h.