SERVICIOS

BTP Aquaforjas Cuenta con un portafolio de servicios especializado, que le permite a los acueductos del país, acceder a excelentes opciones para el mejoramiento del abastecimiento del agua.

BTP Aquaforjas Cuenta con un portafolio de servicios especializado, que le permite a los acueductos del país, acceder a excelentes opciones para el mejoramiento del abastecimiento del agua.

BTP AQUAFORJAS has launched the project for the supply and assembly of the WWTP water pumping station, a station that works with communicated macrometers and pressure sensors developed by our Telemetry Department.

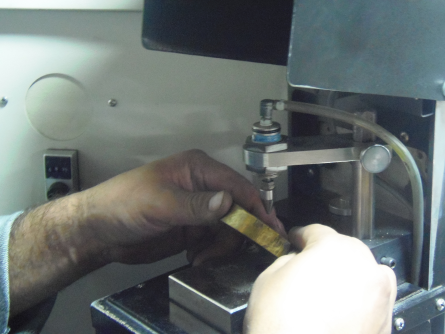

To guarantee the specifications of your products, we carry out exhaustive monitoring and measurement of the material throughout the manufacturing process.

With the performance of quantitative analyzes by spectrometry applied to the different alloys produced, it allows making the necessary adjustments at the time of casting in continuous casting, as well as determining the composition of a sample in order to provide the client with an exact alloy.

Likewise, the qualitative or metallographic analysis of the grain of the material is carried out to determine with what process the piece was made.

BTP AQUAFORJAS has a complete portfolio of products that meet the needs of industries such as mining, transportation and manufacturing nationwide.

We have the service of an accredited laboratory for the calibration of cold drinking water meters, guaranteeing our clients compliance with the NTC ISO/IEC 17025:2017 standard, and ensuring the accuracy of each piece that can range from diameters of 15 to 25 mm and flows from 5 to 6000 l/h in accordance with the NTC 4064-1:2016 and NTC ISO4064-2:2016 standards.

The method used for calibration is to compare the volume registered by the meter with the standard volume stored in a calibrated metal volumetric container, thus determining a percentage calibration error of the meter under test.

Our Laboratory, accredited by ONAC -National Accreditation Body of Colombia- is able to certify its own water meters and offer this service to those who require it.

We offer direct support to the institutions that provide the service, in order to support their management in matters related to the measurement and control of water.

Various workshops are held in the cities of the country, where training is provided according to the need of the institution.

For the installation service of home water connections and smart macro-metering stations, we have a floating staff of operators with extensive experience and backed by ISO 18001 OHSAS accreditation. Our operational and technical capacity obtains results according to the particular needs of companies that provide public services.

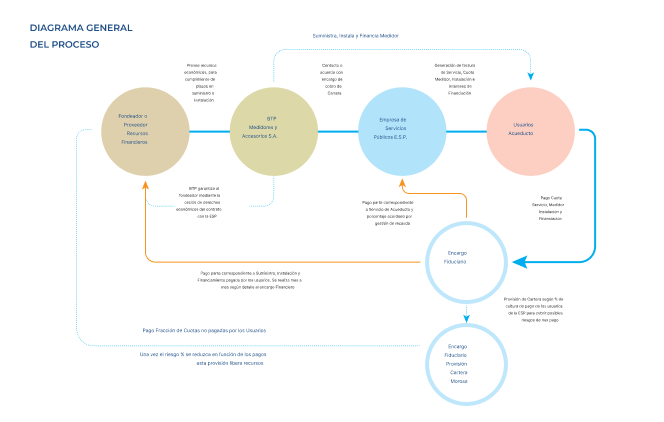

We offer different financing schemes according to the particular needs of the companies that provide public services, their contracting manuals and the current regulations that apply.

Contáctanos!