Our foundry plant has three induction furnaces that have a production capacity of 80,500 and 800 kilos per hour, for the production of ingots, bars, bushings, injected parts and sand molds.

Concentric bronze pieces are manufactured on two machines, one vertical and the other horizontal with outside diameters from 5” to 24” and maximum lengths of 130 centimeters. Manufactured bushings are capable of supporting friction loads from shafts of any size. Other parts such as pinions are capable of supporting power transmission loads.

Through this process the liquid material is transformed

a solid that when passing through a temperature exchange, gives shape to the different alloys. We currently carry out the process with one horizontal and two vertical continuous castings with the capacity to manufacture brass, bronze and copper with diameters of 1″ – 1 1/2″ – 2″, 80mm-120mm and lengths from 1.5 to 4 meters.

These bars are used in the metallurgical industry as raw material for extrusion, stamping and centrifugation processes.

*Non-toxic, non-corrosive, non-polluting material, it has high malleability and machinability, maintaining excellent plasticity and rearrangement.

Our foundry plant has three induction furnaces that have a production capacity of 80,500 and 800 kilos per hour, for the production of ingots, bars, bushings, injected parts and sand molds.

Manufacture of brass parts that require an irregular internal configuration such as taps, accessories for water connections, measurement centers, etc. The manufactured pieces are inscribed in a rectangle of 220mm by 260mm with a maximum weight of 1000 grams.

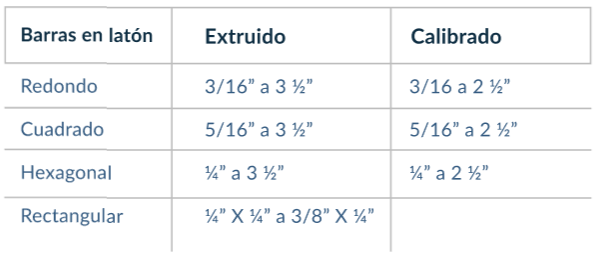

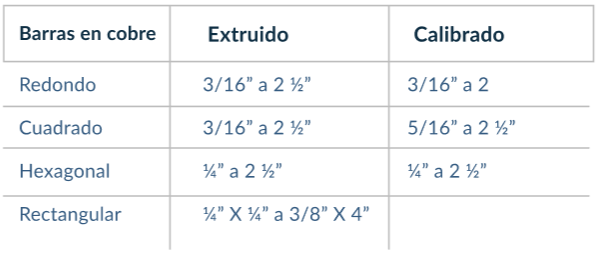

In this process, the metal ingot enters in a superior plastic state, which, when passing through a matrix, is shaped into a wide range of round, hexagonal and square brass and copper bars and profiles, with dimensions ranging from 3/16” to 4 mm. " diameter.

Likewise, industrial, architectural and special profiles are manufactured, with a geometry that can be inscribed in a 130mm diameter circle.

This material is used by the metalworking industry as raw material for the manufacture of machined parts in series as accessories for the conduction of liquids, gases and fuels; nuts, bolts and fittings; parts for electrical conduction; locks, bolts, hinges and accessories.

Contáctanos!